Propress Fitting Failures: Understanding Causes and Prevention

Quick read; ProPress fitting failures can result from improper installation, damaged fittings, corrosion, or overpressurization. Leaks from these failures can cause property water damage, pose safety risks, and lead to costly repairs. Following proper installation and maintenance is essential to prevent these issues and ensure the fittings’ reliability.

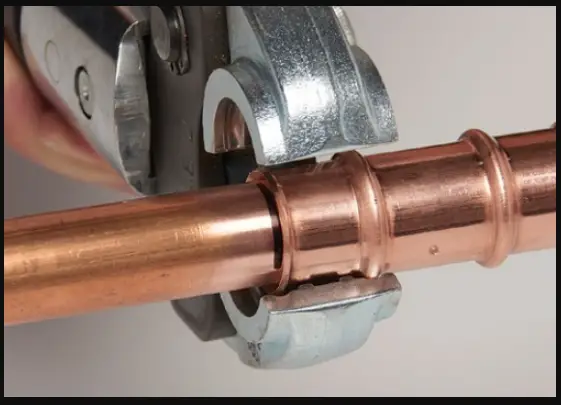

ProPress fittings have revolutionized plumbing with their quick and straightforward installation method. By utilizing crimping instead of soldering or welding, they’ve become a go-to choice for many plumbing applications.

This article delves into an essential aspect of ProPress fittings: the instances where they falter. While they offer efficiency and a leak-free seal, it’s crucial to acknowledge the circumstances under which ProPress fitting failures can occur.

Table of Contents

Are ProPress fittings reliable?

Yes, ProPress fittings are generally reliable when installed correctly. They offer efficient and leak-free connections through crimping, eliminating the need for soldering. Their popularity stems from swift installation and dependable seals.

However, their reliability hinges on proper installation by qualified plumbers. Inaccurate crimping or exposure to harsh conditions can lead to failures. Regular inspection and adherence to guidelines ensure their continued reliability in plumbing systems.

What are the Common Causes of ProPress Fitting Failures?

A. Improper Installation

When it comes to ProPress fittings, proper crimping is paramount. Inadequate crimping can lead to a loose seal, resulting in leaks. This is the most frequent cause of ProPress fitting failures. Precise crimping is a non-negotiable step to ensure a secure connection.

B. Damaged or Defective Fittings

Even though ProPress fittings are robust, they’re not impervious to damage. Accidental drops or exposure to high heat or corrosive chemicals can compromise their structural integrity, leading to potential failures. A small dent or crack might seem inconsequential but can have substantial consequences.

C. Corrosion

Over time, corrosion can sneak in, weakening ProPress fittings. Particularly in environments with harsh chemicals or conditions, corrosion can gradually erode the fittings, creating vulnerabilities that manifest as leaks or other issues. Vigilance against corrosion is essential to prevent these failures.

D. Overpressurization

While ProPress fittings are designed to handle pressure, pushing them beyond their limits can spell disaster. If the pressure exceeds what these fittings can handle, they might give in, causing leaks or even catastrophic failures. Adhering to pressure guidelines is a preventive measure that can’t be ignored.

What are the Effects of ProPress Fitting Failures?

The ramifications of ProPress fitting failures can be substantial. Leaking fittings have the potential to inflict considerable water damage on your property. Left unaddressed, this can lead to costly repairs and structural issues. Moreover, the safety hazard posed by water leakage cannot be underestimated; it can trigger electrical hazards, mold growth, and slippery surfaces.

1. Water Damage:

Leaking ProPress fittings can lead to considerable water damage within your property. The persistent dripping and seepage might start innocuously, but they can saturate walls, floors, and ceilings over time.

This moisture can weaken structures, cause paint to peel, and even compromise the integrity of your property’s foundation. What might begin as a small leak can result in extensive and expensive repairs if left unchecked.

2. Costly Repairs:

Neglecting a leaking ProPress fitting can ultimately drain your finances. The damage caused by water intrusion can extend far beyond the fitting itself. Repairing walls, ceilings, and floors, and rectifying structural issues can quickly add up.

The cost of addressing these damages can be significantly higher than the expense of promptly fixing or replacing the faulty fitting.

3. Structural Issues:

Water damage from leaking fittings can weaken the structural components of your property. Wooden frames can warp, drywall crumble, and even concrete degrade when exposed to excessive moisture. Over time, the compromised structural integrity can endanger the safety of your home or building, making immediate action imperative.

4. Electrical Hazards:

Water and electricity don’t mix. Leaking water can come into contact with electrical wiring, outlets, or appliances, creating a potentially life-threatening situation. Electrical hazards resulting from ProPress fitting failures can lead to short circuits, power outages, or even fires. Protecting yourself and your property from these dangers is crucial.

5. Mold Growth:

Moisture from leaking fittings provides an ideal environment for mold growth. Mold can spread rapidly and release harmful spores into the air, which can cause respiratory issues, allergies, and other health problems. Removing mold can be a complex and expensive process, making it essential to prevent its growth through timely repairs.

6. Slippery Surfaces:

Accumulated water from leaking fittings can create slippery surfaces, posing a risk of falls and injuries. This is particularly hazardous in areas like bathrooms and kitchens. Ensuring that surfaces remain dry and safe is essential for the well-being of occupants.

How to Prevent ProPress Fitting Failures?

Qualified Installation -To avert ProPress fitting failures from the get-go, enlist the services of a qualified plumber. Their expertise ensures that the fittings are crimped accurately and securely, significantly reducing the risk of failures due to improper installation.

Regular Inspection – Regular visual checks of the fittings are crucial. By looking for signs of damage, such as dents, cracks, or discoloration, you can catch potential issues before they escalate into full-blown failures. Early detection is key to preventing water damage and safety hazards.

Avoiding Harsh Chemicals or Conditions – Shielding ProPress fittings from harsh chemicals and adverse conditions is essential. If possible, choose alternative materials or fittings for applications where exposure to corrosive substances is inevitable. This proactive approach can extend the lifespan of your fittings.

Proper Pressure Management – Stay within the recommended pressure limits for your ProPress fittings. This requires careful planning and consideration of the system’s requirements. Avoid the temptation to push the limits, as overpressurization can lead to avoidable failures.

Does My Landlord Have To Reglaze My Tub? All You Need To Know

plumbinsight.com

What are the advantages and disadvantages of ProPress fittings?

here’s a table outlining the advantages and disadvantages of ProPress fittings along with their descriptions:

| Advantages of ProPress Fittings | Description |

|---|---|

| 1. Efficient Installation | ProPress fittings allow for fast connection without soldering or welding, reducing installation time. |

| 2. Leak-Free Seals | When crimped correctly, ProPress fittings offer reliable, leak-free seals, ensuring the integrity of the system. |

| 3. Safety | The absence of open flames or welding reduces the risk of fire hazards, enhancing safety during installation. |

| 4. Material Versatility | ProPress fittings can be used with various pipe materials like copper, stainless steel, and PEX, increasing flexibility. |

| 5. Minimal Downtime | Rapid connections mean shorter system shutdowns during installation or repairs, reducing disruptions. |

| 6. Neat Appearance | The clean process eliminates the need for flux or solder, resulting in a tidy and professional finish. |

| 7. Consistent Seals | Mechanically precise crimps lead to uniform and dependable seals, ensuring consistent performance. |

| 8. No Hot Work Permits Required | As there are no open flames involved, ProPress installations often don’t require hot work permits. |

| Disadvantages of ProPress Fittings | Description |

|---|---|

| 1. Higher Cost | Both ProPress fittings and the specialized tools needed for installation can be more expensive compared to traditional methods. |

| 2. Skill Required | Proper crimping technique requires training and expertise, which might increase the need for skilled labor. |

| 3. Tool Dependency | Specific crimping tools are essential for installation, which can lead to delays if tools are unavailable. |

| 4. Limited Accessibility | In tight spaces or areas with limited access, using crimping tools can be challenging, affecting installation. |

| 5. Long-Term Reliability Uncertainty | While ProPress fittings are reliable when installed correctly, questions about long-term durability remain. |

| 6. Concealed Crimp Inspection | Inspecting concealed crimps can be difficult, potentially leading to undetected issues until problems arise. |

ProPress fittings offer efficient, safe, and reliable connections but come with considerations such as costs, skill requirements, and potential challenges in inspection and tight spaces.

How Hard Is The Journeyman Plumber Test? All You Need To Know

plumbinsight.com

How long do press fittings last?

The lifespan of press fittings varies depending on factors like installation quality, usage conditions, and the environment. Generally, when correctly installed by a skilled professional and maintained well, press fittings can last for decades.

However, exposure to corrosive substances, extreme temperatures, or excessive pressure can reduce their longevity. Routine inspections, prompt repairs, and avoiding harsh conditions can extend their lifespan, ensuring many years of efficient and leak-free plumbing connections. Regular monitoring and adherence to manufacturer guidelines contribute to the durability and reliability of press fittings over the long term.

Conclusion

In the realm of plumbing, ProPress fittings provide efficiency and convenience. However, they are not exempt from the potential for failures. Understanding the common causes of ProPress fitting failures, recognizing their effects, and implementing preventive measures are crucial for maintaining a leak-free plumbing system. By adhering to proper installation techniques, regular inspections, cautious material selection, and pressure management, you can ensure that your ProPress fittings stand the test of time, contributing to a secure and efficient plumbing infrastructure.